VEarth

Home > VEarth

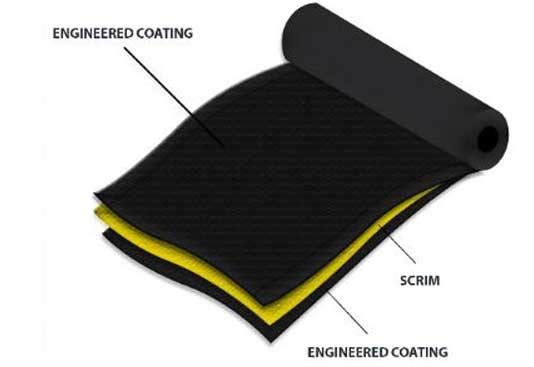

Geomembrane 12 mil

Product Description

A lightweight high-performance fabric manufactured using the finest grade of high-density polyethylene.

Recommended Application

Daily and temporary landfill covers, Field covers,

Agricultural covers.

Features and benefits

-

Advanced heat sealing for

robust on-site installation. -

Enhanced heat sealing = superior

durability.

-

Exceptional U.V. resistance

for lasting protection. -

Impressive chemical resistance

guards against corrosion.

- Reliable water resistance prevents moisture damage.

-

Flawless finish with guaranteed

absence of defects.

Availability

- Roll Width: Up to 156 inches.

- Warranty: 5 years (exposed), 10 years (buried)

Geomembrane 12 mil | Technical Datasheet

| Specification | Test Standard | Unit | Typical Value |

| Thickness | ASTM D1777 | Mils | 12 |

| Strip Tensile (Grab Method) | ASTM D7004 | lbs | MD: 215 CD: 205 |

| Strip Tensile | ASTM D7003 | lbs/inch | MD: 130 CD:130 |

| Tongue Tear | ASTM D5884 | lbs | MD: 85 CD: 90 |

| Mullan Burst | ASTM D751 | psi | 375 |

| Hydrostatic Resistance | AASTM D751 | psi | 71 |

| Index Puncture Resistance | ASTM D4833 | lbs | 105.00 |

| CBR Static Puncture | ASTM D6241 | lbs | 615.00 |

| Carbon Black Content (%) | ASTM D4218 | % | 3.30 |

| Dimensional Stability | ASTM D1204 | % | MD: -6.14 CD: -4.16 |

| Low-Temperature Flexibility | ASTM D2136 | - | MD & CD: Pass @ -29°C |

| HP-OIT (After QUV Ageing) | ASTM D5885 | Minutes | 50 |

| Accelerated UV Weathering* | ASTM D7238 | % Retained | MD: 95 CD: 95 |

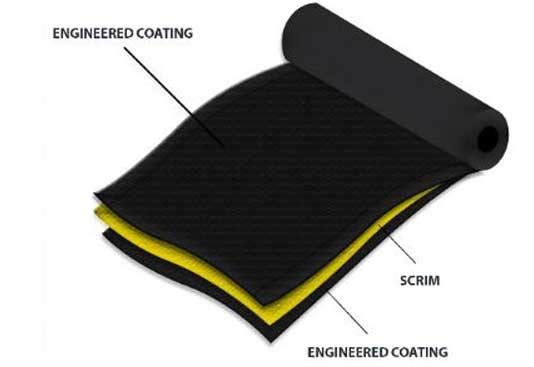

Geomembrane 20 mil

Product Description

A heavyweight high-performance industrial fabric manufactured using the finest grade of high-density polyethylene to improve toughness and abrasion resistance.

Recommended Applications

Features and benefits

-

Advanced heat sealing for

robust on-site installation. -

Enhanced heat sealing = superior

durability.

-

Exceptional U.V. resistance

for lasting protection. -

Impressive chemical resistance

guards against corrosion.

- Reliable water resistance prevents moisture damage.

-

Flawless finish with guaranteed

absence of defects.

Availability

- Roll Width: Up to 156 inches.

- Warranty: 5 years (exposed), 10 years (buried)

Geomembrane 20 mil | Technical Datasheet

| Specification | Test Standard | Unit | Typical Value |

| Thickness | ASTM D1777 | Mils | 20 |

| Strip Tensile (Grab Method) | ASTM D7004 | lbs | MD: 310 CD: 305 |

| Strip Tensile | ASTM D7003 | lbs/inch | MD: 220 CD: 215 |

| Tongue Tear | ASTM D5884 | lbs | MD: 75 CD: 70 |

| Mullan Burst | ASTM D751 | psi | 635 |

| Hydrostatic Resistance | AASTM D751 | psi | 173 |

| Index Puncture Resistance | ASTM D4833 | lbs | 155.0 |

| CBR Static Puncture | ASTM D6241 | lbs | 1050.0 |

| Carbon Black Content (%) | ASTM D4218 | % | 3.20 |

| Dimensional Stability | ASTM D1204 | % | MD: -2.92 CD: -2.39 |

| Low-Temperature Flexibility | ASTM D2136 | - | MD & CD: Pass @ -29°C |

| HP-OIT (After QUV Ageing) | ASTM D5885 | Minutes | 50 |

| Accelerated UV Weathering* | ASTM D7238 | % Retained | MD: 95 CD: 95 |

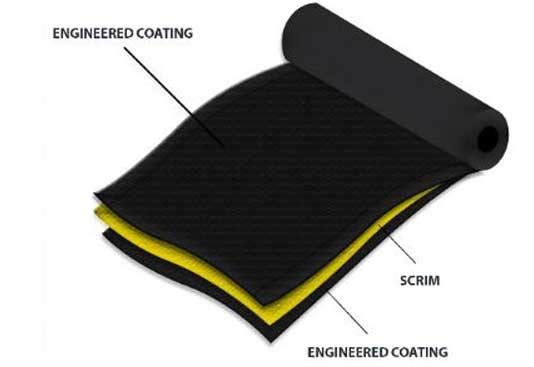

Geomembrane 24 mil

Product Description

A heavyweight high-performance industrial fabric manufactured using the finest grade of high-density polyethylene to enhance puncture, flatness, and tear properties.

Recommended Applications

Shale oil and gas development, e.g., drill pads and various liquid containment &Water reservoirs and ponds

Features and benefits

-

Advanced heat sealing for

robust on-site installation. -

Enhanced heat sealing = superior

durability.

-

Exceptional U.V. resistance

for lasting protection. -

Impressive chemical resistance

guards against corrosion.

- Reliable water resistance prevents moisture damage.

-

Flawless finish with guaranteed

absence of defects.

Availability

- Roll Width: Up to 156 inches.

- Warranty: 5 years (exposed), 10 years (buried)

Geomembrane 24 mil | Technical Datasheet

| Specification | Test Standard | Unit | Typical Value |

| Thickness | ASTM D1777 | Mils | 24 |

| Strip Tensile (Grab Method) | ASTM D7004 | lbs | MD: 425 CD: 420 |

| Strip Tensile | ASTM D7003 | lbs/inch | MD: 225 CD: 220 |

| Tongue Tear | ASTM D5884 | lbs | MD: 120 CD: 170 |

| Mullan Burst | ASTM D751 | psi | 778 |

| Hydrostatic Resistance | AASTM D751 | psi | 185 |

| Index Puncture Resistance | ASTM D4833 | lbs | 203 |

| CBR Static Puncture | ASTM D6241 | lbs | 1283 |

| Carbon Black Content (%) | ASTM D4218 | % | 3.30 |

| Dimensional Stability | ASTM D1204 | % | MD: -4.34 CD: -3.36 |

| Low-Temperature Flexibility | ASTM D2136 | - | MD & CD: Pass @ -29°C |

| HP-OIT (After QUV Ageing) | ASTM D5885 | Minutes | 50 |

| Accelerated UV Weathering* | ASTM D7238 | % Retained | MD: 95 CD: 95 |

Geomembrane 30 mil

Product Description

A heavyweight high-performance industrial fabric manufactured using the finest grade of high-density polyethylene to enhance puncture, flatness, and tear properties. The product is designed to improve toughness and abrasion resistance for exposed applications.

Recommended Applications

Water reservoirs and ponds, Soil remediation pads, Interim and final landfill and Mine Reclamation cover systems & Shale oil and gas development, e.g., drill pads and various liquid containment.

Features and benefits

-

Advanced heat sealing for

robust on-site installation. -

Exceptional U.V. resistance

for lasting protection.

- Impressive chemical resistance guards against corrosion.

- Reliable water resistance prevents moisture damage.

- Tailored for slope applications with superior traction.

-

Flawless finish with guaranteed

absence of defects.

Availability

- Roll Width: Up to 156 inches.

- Warranty: 10 years (exposed), 20 years (buried)

VEarth Geomembrane 30 mil | Technical Datasheet

| Specification | Test Standard | Unit | Typical Value |

| Thickness | ASTM D1777 | Mils | 30 |

| Strip Tensile (Grab Method) | ASTM D7004 | lbs | MD: 460 CD: 390 |

| Strip Tensile | ASTM D7003 | lbs/inch | MD: 265 CD: 260 |

| Tongue Tear | ASTM D5884 | lbs | MD: 125 CD: 120 |

| Mullan Burst | ASTM D751 | psi | 785 |

| Hydrostatic Resistance | AASTM D751 | psi | 388 |

| Index Puncture Resistance | ASTM D4833 | lbs | 186 |

| CBR Static Puncture | ASTM D6241 | lbs | 1250 |

| Carbon Black Content (%) | ASTM D4218 | % | 3.95 |

| Dimensional Stability | ASTM D1204 | % | MD: -1.92 CD: -1.35 |

| Low-Temperature Flexibility | ASTM D2136 | - | MD & CD: Pass @ -29°C |

| HP-OIT (After QUV Ageing) | ASTM D5885 | Minutes | 80 |

| Accelerated UV Weathering* | ASTM D7238 | % Retained | MD: 95 CD: 95 |

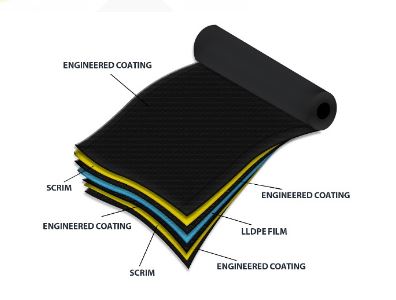

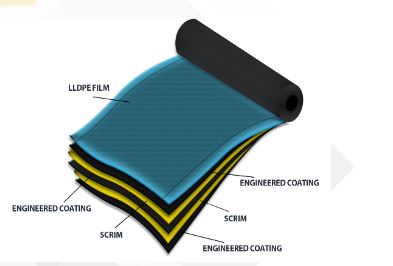

VEarth Geomembrane 30HP| Product Description

Product Description

A heavyweight high-performance industrial fabric designed to enhance thickness, flatness, and tear properties. This product has a one side laminated LLDPE film to improve toughness and abrasion resistance. This product is intended for long term buried or exposed applications.

Recommended Applications

Water reservoirs and ponds, Shale oil and gas development, e.g., drill pads and various liquid containment & Oil and gas production, e.g., various secondary containment applications

Features and benefits

-

Advanced heat sealing for

robust on-site installation. -

Exceptional U.V. resistance

for lasting protection.

- Impressive chemical resistance guards against corrosion.

- Reliable water resistance prevents moisture damage.

-

Flawless finish with guaranteed

absence of defects.

Availability

- Roll Width: Up to 156 inches.

- Warranty: 20 years (exposed), 25 years (buried)

VEarth Geomembrane 30HP| Technical Datasheet

| Specification | Test Standard | Unit | Typical Value |

| Thickness | ASTM D1777 | Mils | 30 |

| Strip Tensile (Grab Method) | ASTM D7004 | lbs | MD: 470 CD: 400 |

| Strip Tensile | ASTM D7003 | lbs/inch | MD: 270 CD: 265 |

| Tongue Tear | ASTM D5884 | lbs | MD: 130 CD: 125 |

| Mullan Burst | ASTM D751 | psi | 790 |

| Hydrostatic Resistance | AASTM D751 | psi | 400 |

| Index Puncture Resistance | ASTM D4833 | lbs | 190 |

| CBR Static Puncture | ASTM D6241 | lbs | 1275 |

| Carbon Black Content (%) | ASTM D4218 | % | 3.95 |

| Dimensional Stability | ASTM D1204 | % | MD: -1.92 CD: -1.35 |

| Low-Temperature Flexibility | ASTM D2136 | - | MD & CD: Pass @ -29°C |

| HP-OIT (After QUV Ageing) | ASTM D5885 | Minutes | 80 |

| Accelerated UV Weathering* | ASTM D7238 | % Retained | MD: 95 CD: 95 |

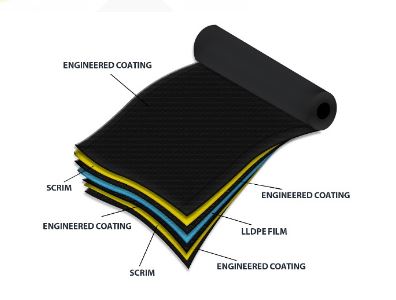

VEarth Geomembrane 40mil

Product Description

A double scrim, heavyweight geomembrane fabric incorporating a special weave pattern to enhance thickness, flatness, and tear properties. The product is designed to improve toughness and abrasion resistance for exposed applications requiring extremely high puncture resistance and tensile strength.

Recommended Applications

Interim and final landfill and Mine Reclamation cover systems & Long-term covers to exposed areas.

Features and benefits

-

Advanced heat sealing for

robust on-site installation. -

Exceptional U.V. resistance

for lasting protection.

- Impressive chemical resistance guards against corrosion.

- Reliable water resistance prevents moisture damage.

- Tailored for slope applications with superior traction.

-

Flawless finish with guaranteed

absence of defects.

Availability

- Roll Width: Up to 156 inches.

- Warranty: 20 years (exposed), 25 years (buried)

VEarth Geomembrane 30HP| Technical Datasheet

| Specification | Test Standard | Unit | Typical Value |

| Thickness | ASTM D1777 | Mils | 40 |

| Strip Tensile (Grab Method) | ASTM D7004 | lbs | MD: 670 CD: 575 |

| Strip Tensile | ASTM D7003 | lbs/inch | MD: 440 CD: 320 |

| Tongue Tear | ASTM D5884 | lbs | MD: 175 CD: 170 |

| Mullan Burst | ASTM D751 | psi | 1015 |

| Hydrostatic Resistance | AASTM D751 | psi | 595 |

| Index Puncture Resistance | ASTM D4833 | lbs | 260.00 |

| CBR Static Puncture | ASTM D6241 | lbs | 1800.00 |

| Carbon Black Content (%) | ASTM D4218 | % | 3.41 |

| Dimensional Stability | ASTM D1204 | % | MD: -2.99 CD: -2.42 |

| Low-Temperature Flexibility | ASTM D2136 | - | MD & CD: Pass @ -29°C |

| HP-OIT (After QUV Ageing) | ASTM D5885 | Minutes | 212 |

| Accelerated UV Weathering* | ASTM D7238 | % Retained | MD: 95 CD: 95 |