The significant losses occur when metallic products are damaged or lost, due to rust and corrosion. To Avoid such losses the manufacturers concentrate their efforts on corrosion control and prevention during packaging, shipping and storage. The conventional methods to control corrosion through paint, grease and wax, are messy, time consuming and expensive. These methods also pose a potential threat to the environment unless properly treated and disposed. An alternative way to protect metals against corrosion – without dipping, cleaning, expensive waste treatment and without damaging the environment is represented by Volatile Corrosion Inhibitors – VCI.

Classification of Corrosion

Corrosion

- Degradation of Materials

- Metal Loss

- De-Colorization

- Pits

- Damage due to erosion

- De Lamination

- Cracking, buckling

Types of Corrosive Gases

- Nitrous Oxides (NOx)

- Ozone (O3) – reactive oxygen

- Hydrogen Sulfide (H2S) and Sulfur Dioxides (SO2)

- Carbonyl Sulfide (COS)

- Hydrogen Chloride (HCl)

- Corrosive gases from wood off gassing

Corrosion results in estimated loss of 200 billions of dollars. The problem is largely avoidable by proper maintenance and protection methods.

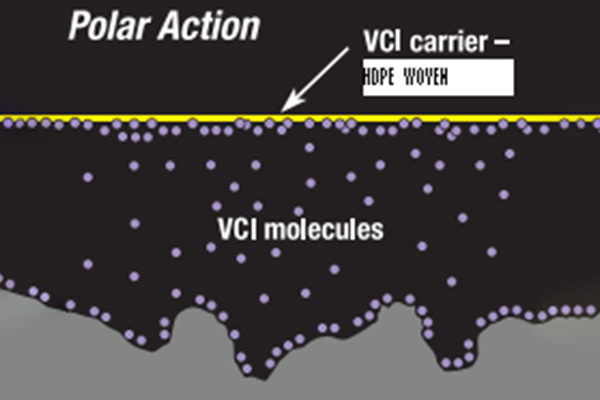

Vapor Corrosion Inhibitor’s Action

How Metal Wrap Work

When metals are wrapped or packaged in Metal Wrap, the chemicals volatilize in the packaging environment and form a protective molecular layer on the surface of the metal. This protective layer prevents moisture, salt, dirt, oxygen and other materials from depositing on the metal and causing corrosion. Simply store or ship metal parts in Veer Metal Wrap packaging. When the parts are unwrapped, the protective layer immediately begins to dissipate. The metal parts are clean, corrosion free and ready to use. No washing, dipping or cleaning is necessary.

- Long lasting, effective protection against corrosion

- Easy, clean, economical application options

- Easy storage

- Lower per unit packaging

- Packaging flexibility

- Reduced processing time

- High Tensile strength fabric.

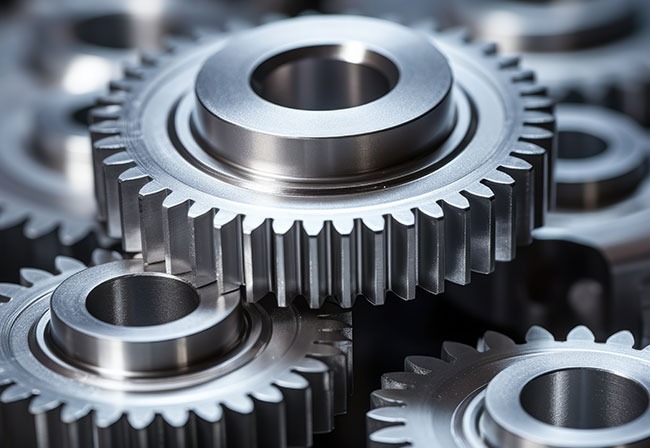

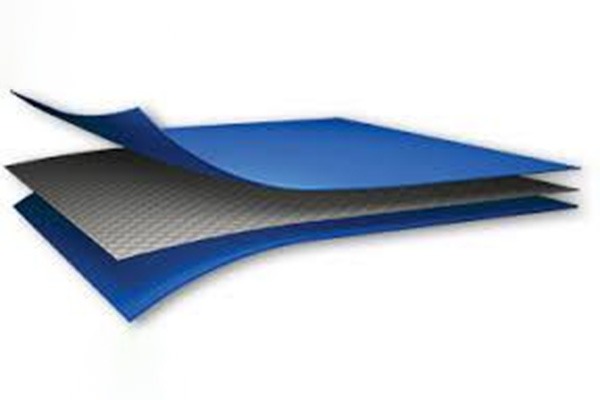

Metal Wrap protect both Ferrous as well as non-ferrous Metals from corrosion. VCI protection may be administered to metal components through elements of packaging and preservation. Multilayer Woven PP/HDPE product is one of the principal elements used in packaging. Special VCI impregnated woven product have been developed at Veer Group for packaging of metal components. These are plain and multi-layered products, ideally suited for over-wrapping as well as packaging of semi-finished or finished metal components. Suitable for Ferrous, Aluminum, Aluminum Alloy components and / or non-ferrous metal components such as those made from copper or brass. The multi-layered sheets are woven PP/ HDPE-fabric laminated, having adequate strength and waterproof qualities. These sheets may be used in the form of covers, which provide moisture-resistant and tear resistant protection to the packed items. (Since the VCI field created within the package covers a sizeable volume, the package can also be a loose fit.)

Potential End Use

Steel Wrap - Coils, Flat Sheets

Tubular steel, steel beams and sections

Metal parts (auto, heavy equipment, etc.)

Metal construction materials

Oil rigs and drilling equipment (mothball/storage applications)

Military equipment or arms covers

Application to Industries

Steel

Non Ferrous –Alloy

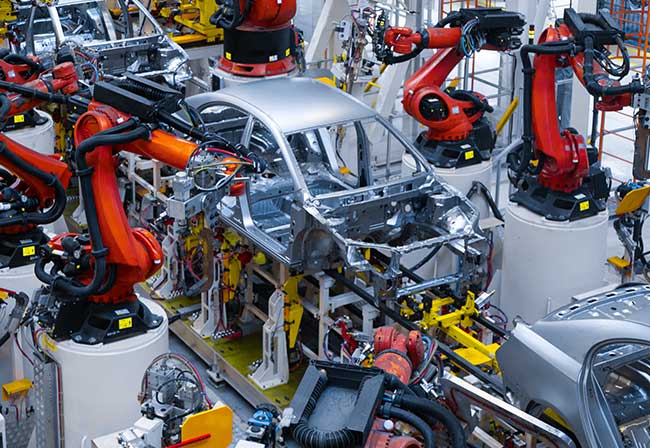

Automobile

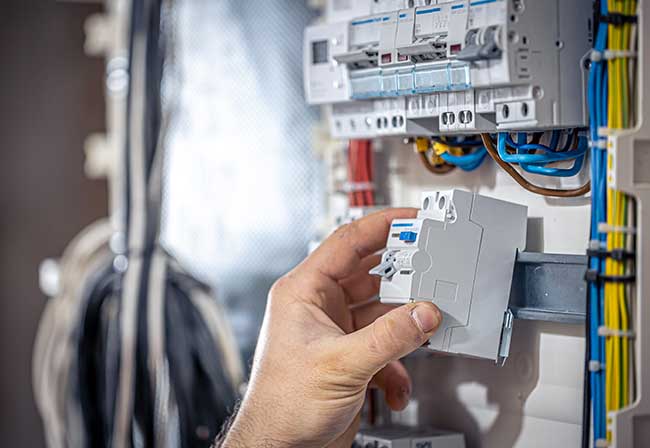

Electricals

Shipping

Aerospace

Heavy Equipment

Railways

Spare Parts

Electronics

Light Engineering

Machines

Steel

Non Ferrous –Alloy

Automobile

Electricals

Shipping

Aerospace

Heavy Equipment

Railways

Spare Parts

Electronics

Light Engineering

Machines

Function

In addition to acting as a barrier to external atmospheric gases the Metal Wrap scavenges any corrosive gases that might be enclosed in the air space inside the package.

Advantages

- Large shipments regardless of size and shape can be fully protected

- Barrier material more than adequate to give sufficient strength to the package

- Due to continuous presence of VCI, packaged items remain protected even in case of a leak in the sealing

- Costly machines can remain packed in the open condition awaiting installation for longer periods

- Protects the components for as long as 6-10 months

- The multiple cover system from Metal Wrap can provides extra strength to the package. This eliminates damage during transit or handling

- Materials used being non-toxic and recyclable, they are easy to dispose and contribute to maintaining the environmental balance

- Offers multi-metal Protection

- Reduces over all packing cost.

- Combination of different barrier materials possible with PP Raffia & PP Spunbonded non woven range of materials,.

Features & Benefits

Veer Plastics produces Polypropylene and High Density Polyethylene based Metal Wraps, finished as metal wrap rolls; available in widths up to 144”, 3.6m.

- Fabrics specifically engineered to protect against abrasion, weather and handling or transit damages

- 3 layer design provides excellent tear strength and puncture resistance

- Made from a blend of 100% recyclable polypropylene

- Available in Widths: up to 144”

- Minimal elongation so that packaging retains shape

- All Veer Plastics Metal Wrap grades are engineered to operate with industry standard packaging systems

- Flexible material for ease of packaging and pliability between -40°F to 180°F

- Evenly spaced reinforcing tapes provide a flat uniform surface

- 4 color high quality custom printing

- Ultraviolet stabilizing additives for higher UV Stability

- VCI technology offering high corrosion resistance

- Resistant to mold and mildew

Why Veer Plastics

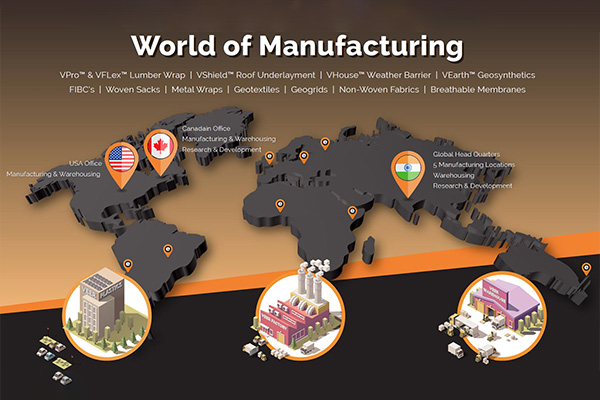

- Strategic locations of woven & non-woven manufacturing plants

- Focused on customer satisfaction

- On-time delivery performance

- Comprehensive in-house quality testing

- Continuous R&D and product innovation

- Lean production processes

- Transparent business practices

- Strong investment capabilities

- Consistent growth

Company Highlights

- Veer Plastics – Established in 1985 – ISO 9001:2008

- Privately owned family company

- Annual Sales over $100 million

- Over 2,400 employees worldwide

- Fully integrated manufacturer of coated woven and non woven

polyolefin products. - Customer focused innovations with speed to market

- Expanding Globally: Manufacturing, Distribution and Markets

Quality Policy

- Voice of the Customer (VOC)

- ZERO Defects Fabrics

- IS0 9001:2008

- Lean Manufacturing

- Fully integrated manufacturer

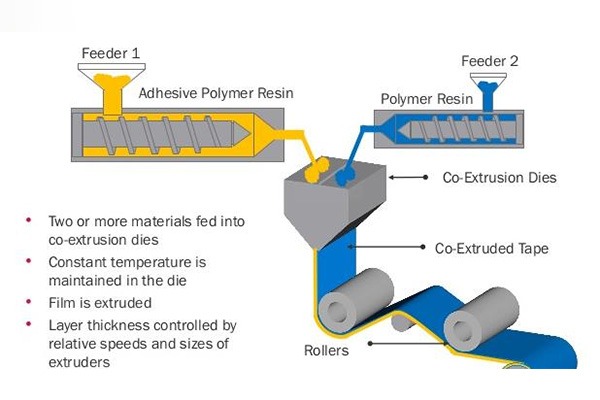

Veer Plastics Engineered Technology

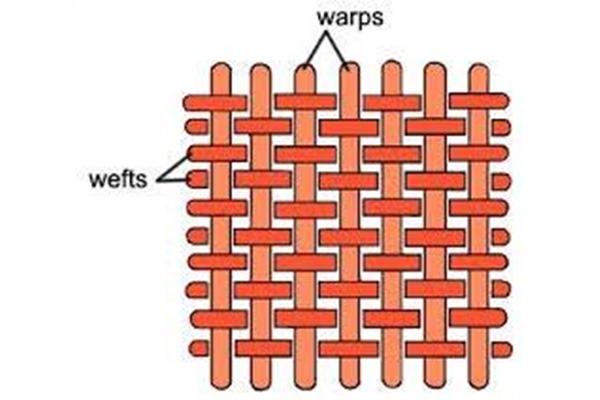

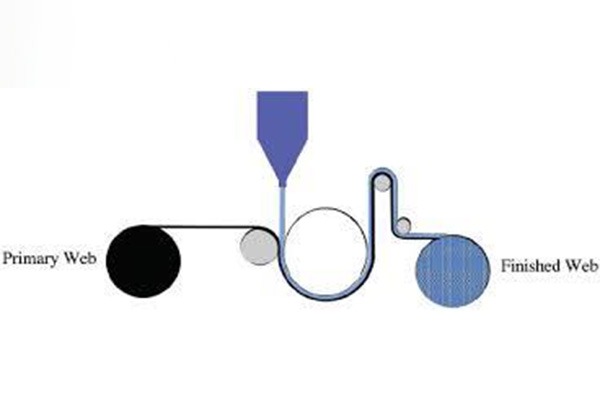

Standard 2 side coated woven – 3 Layer

Coatings

- VCI Coating

- Protection

- Waterproofing

- Colour of choice

Scrim

- Strength

- Thickness

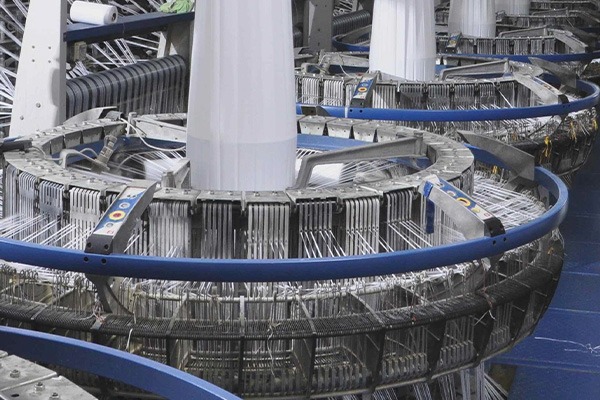

Core Manufacturing Capabilities

- With 5 established major manufacturing locations in India and 2 in North

America, Veer Plastics have over 1 million square feet of manufacturing facilities. - Our equipment portfolio includes:

• 15 tape extrusion lines

• 532 weaving circular looms – Weaving range of 30cms to 500cms (5mtrs)

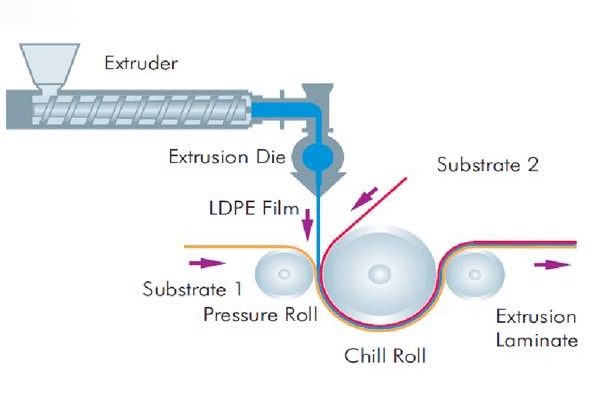

• 9 extrusion coating lines up to 165” (4.2 M)

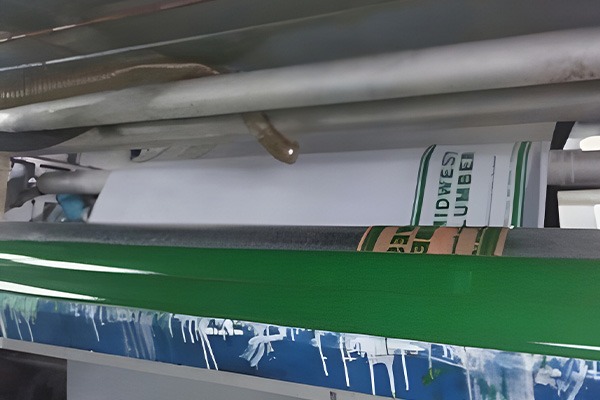

• 16 printing presses up to 134” (3.6 M)

• 16 slitting, cutting and rewinding machines

• 12 auto converting lines; 150+ sewing & 2 heat sealing

• 1 non-woven up to 126”, laminating, paper, foil

• 1 self adhesive, butyl, asphalt & hot melt up to 60”

• Breathable (Vapour permeable) Membranes

Process Overview

Tape Extrusion Line

Output: Bobbin of Tape

Input: Polymer Pellets

Weaving

Coating Lamination

Coating Lamination Options

Customizing

Printing

- Solvent and Water Based

- 4 color

- Speeds up to 700 ft/min

Rewinding

- Master or Jumbo rolls are

made into finished roll

length and width - All defects are removed

Robust Infrastructure

Ensuring Industrial Safety with Cordoned Walls, CCTV Surveillance, Security Personnel

Clean and Dust Free Facility

Best of Manufacturing Line

Plant Area

Fabric Looms

Lab Testing facility

Rejection Area